Establishment of a Carbon-neutral Society

While the worldwide movement of decarbonization has accelerated, the Tokai Rika Group has been enhancing activities we consider to be the responsibility of a global company, and has been promoting CO2 reduction activities within the whole group. These activities include downsizing and reducing the weight of products, which contributes to the improvement of fuel efficiency of vehicles, and improving the efficiency of the use of energy in production and transportation.

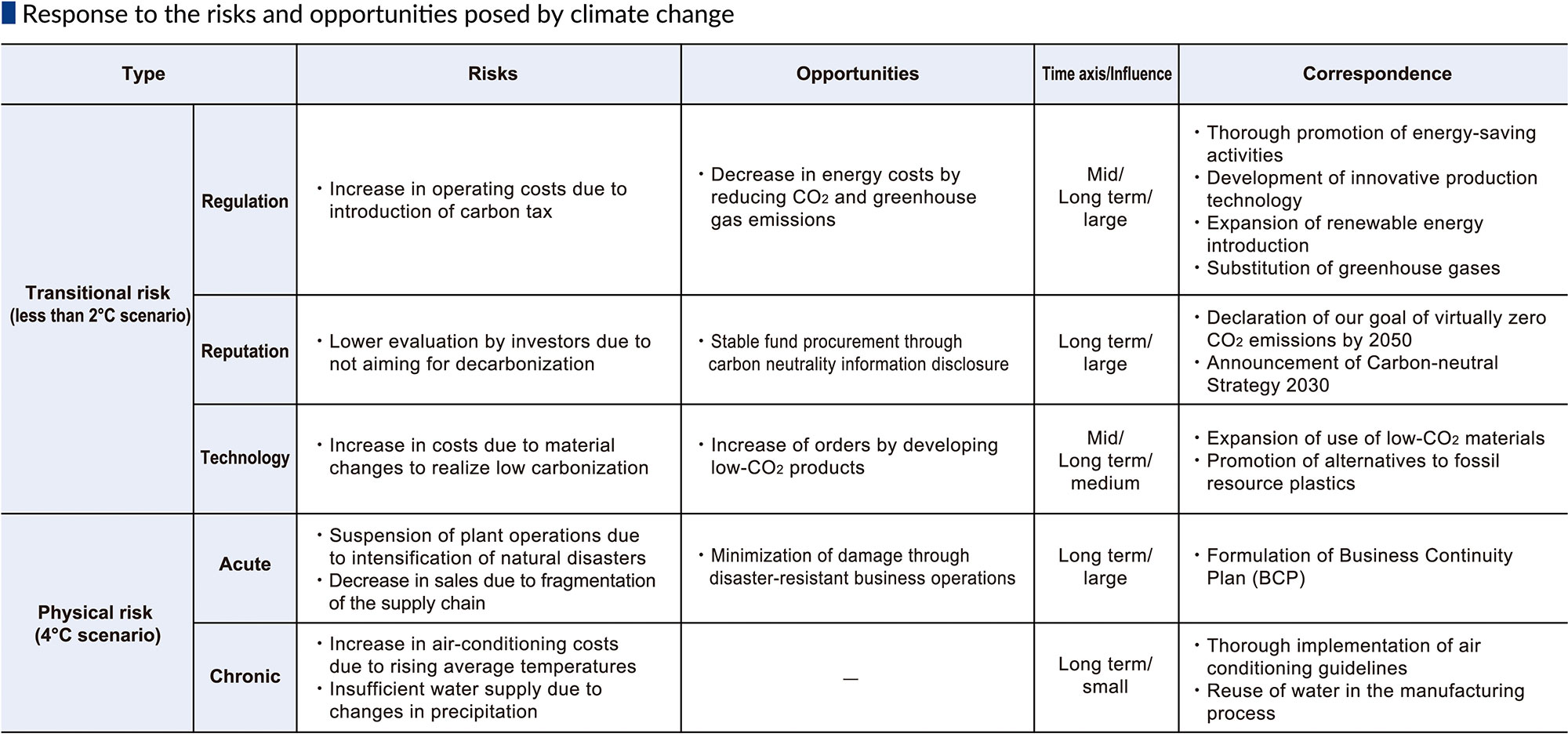

Scenario Analysis Regarding Climate Change

In order to understand the risks and opportunities that climate change poses to our business activities, we have selected and analyzed multiple climate change scenarios. We will respond to the extrapolated transitional and physical risks.

Promotion of Low-CO2 Design in Products

We are promoting low-CO2 design in our products, such as use of alternatives to fossil resource plastics, expansion of use of low-CO2 materials, and promotion of lighter and more compact designs to improve vehicle fuel efficiency.

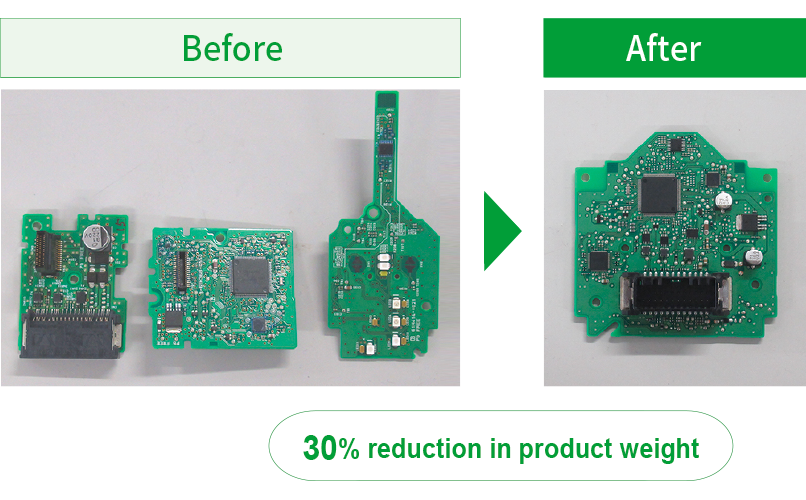

Promotion of more compact and lightweight designs for products

Regarding the shift by wire ECU, we have reduced the board CP configuration from 3 to 1 through drastic redesigning. This improvement has reduced the product weight by approximately 30%.

Development of bamboo-plastic composite material

We have developed and produced automotive parts made from wood and bamboo. We have started to take on the challenge of further evolving these technologies to develop sustainable materials. This product has the same characteristics as the resin material ‘‘ABS’’, which is derived from fossil resources, while effectively reducing CO2 emissions from the material to less than 50%. By using cut-down bamboo for bamboo grove maintenance as a raw material, we aim to contribute to Satoyama preservation and to the creation of a sustainable environment and society.

Reduction of Energy CO2 Emissions

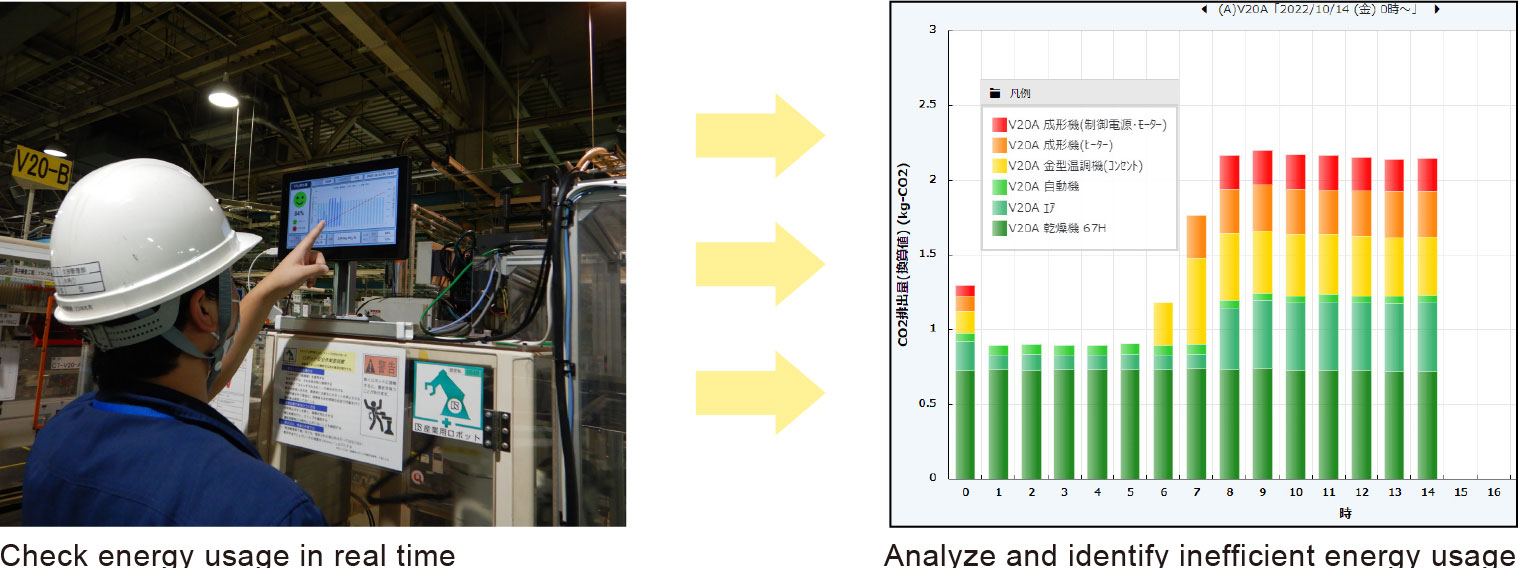

We are promoting activities to reduce CO2 emissions, such as thorough streamlining of production processes, global deployment of examples of energy-saving improvements, and expansion of the introduction of renewable energy. In addition, by collecting energy usage data for each process and displaying targets and results in real time, we have built a production energy visualization system that makes it easier to notice waste on site. The acquired data can be viewed remotely via energy management software, and is used for data analysis to identify inefficient energy usage.

Reduction of CO2 in plants

We have organized a working group for each process such as molding, casting, semiconductor, plating, and heat treatment to promote thorough energy saving of production equipment.

In FY 2020, we implemented 718 improvements and were able to reduce 1,848 t-CO2. Among the improvement cases implemented, those with particularly excellent applicability and viewpoints are given in-house awards to raise employee awareness and horizontally deploy them to other plants.

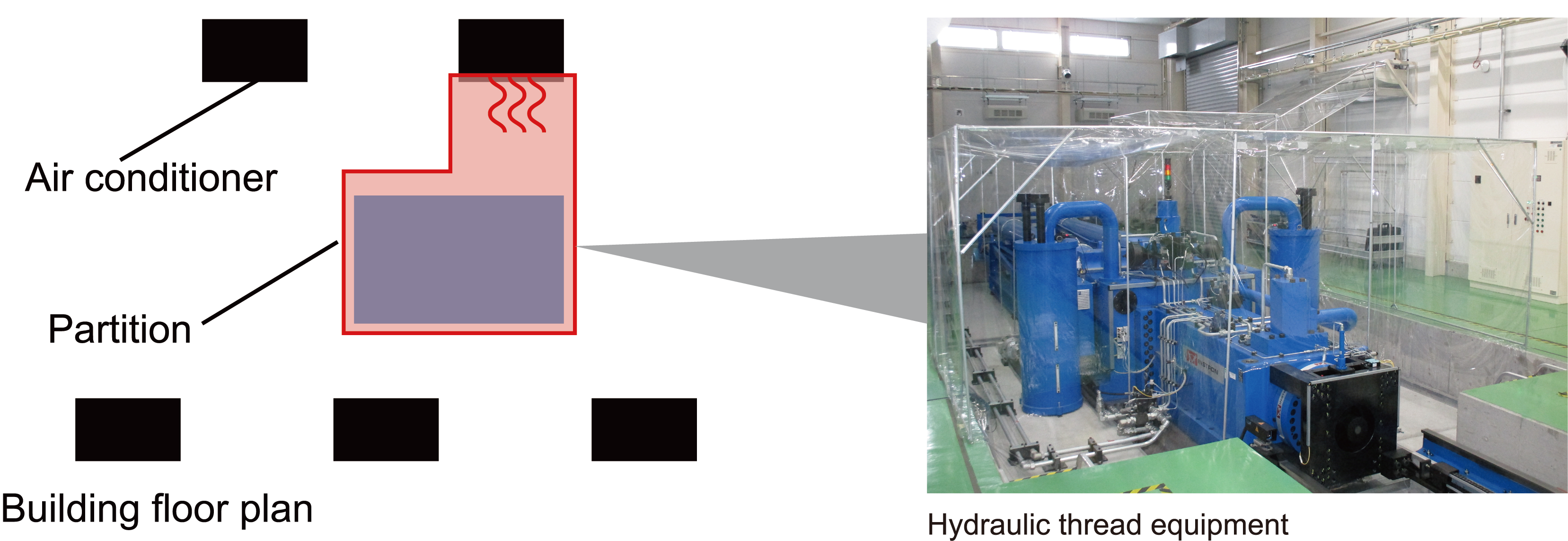

Reduction of the number of air conditioners in operation by partitioning hydraulic equipment

Hydraulic thread equipment requires oil temperature control to maintain operational accuracy; until now the room temperature was adjusted by the building's air conditioner. We have reduced the number of operating air conditioners by four units, by installing vinyl partitions around the equipment and individualizing the operation control of the nearest air conditioner. This improvement has reduced CO2 emissions by 19.4t-CO2 annually.

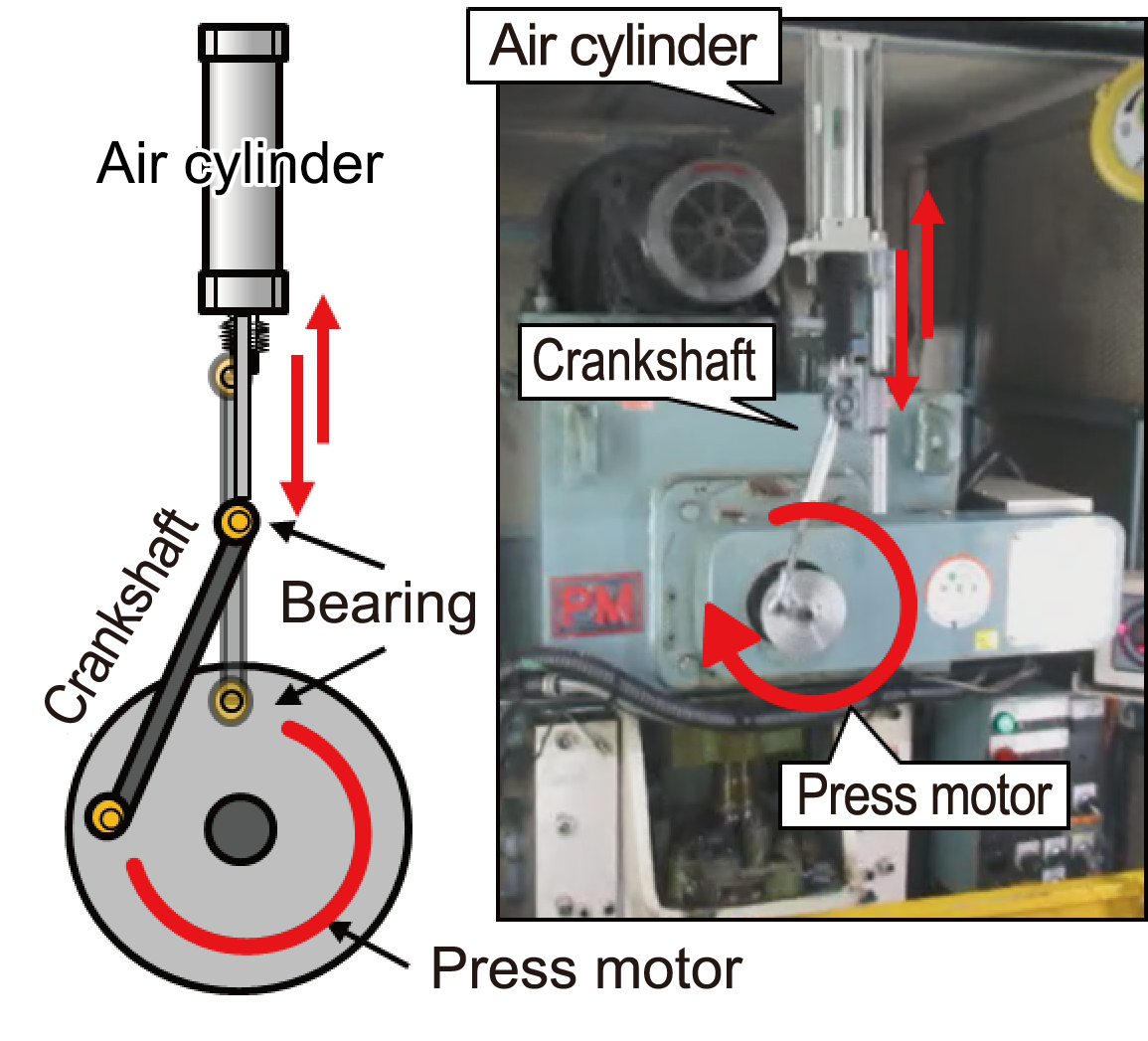

Promotion of non-powered press machine through Karakuri (gimmick) improvement

Automation through Karakuri not only improves workability, but also reduces the use of electricity to zero, leading to a reduction of CO2 emissions.

In the press process, by applying Karakuri to the crankshaft, the rotary motion of the motor is converted into the reciprocating motion of the cylinder to generate the compressed air used to discharge the scrap. This improvement made it possible to abolish the plant air supply, reducing CO2 emissions by 2.85t-CO2 annually.

Use of renewable energy

We aim for renewable energy to account for more than 25% of our power consumption by 2030, and are promoting the introduction of renewable energy such as solar power generation. In FY 2021, we introduced solar power generation at our Hagi Plant and TRT (Thailand), and the renewable energy rate has improved to 8.0%. In FY 2022, in addition to the on-site introduction that has been promoted so far, we are planning a new off-site introduction, and we expect to improve the renewable energy rate to 13.4%.

We aim for renewable energy to account for more than 25% of our power consumption by 2030, and are promoting the introduction of renewable energy such as solar power generation. In FY 2021, we introduced solar power generation at our Hagi Plant and TRT (Thailand), and the renewable energy rate has improved to 8.0%. In FY 2022, in addition to the on-site introduction that has been promoted so far, we are planning a new off-site introduction, and we expect to improve the renewable energy rate to 13.4%.

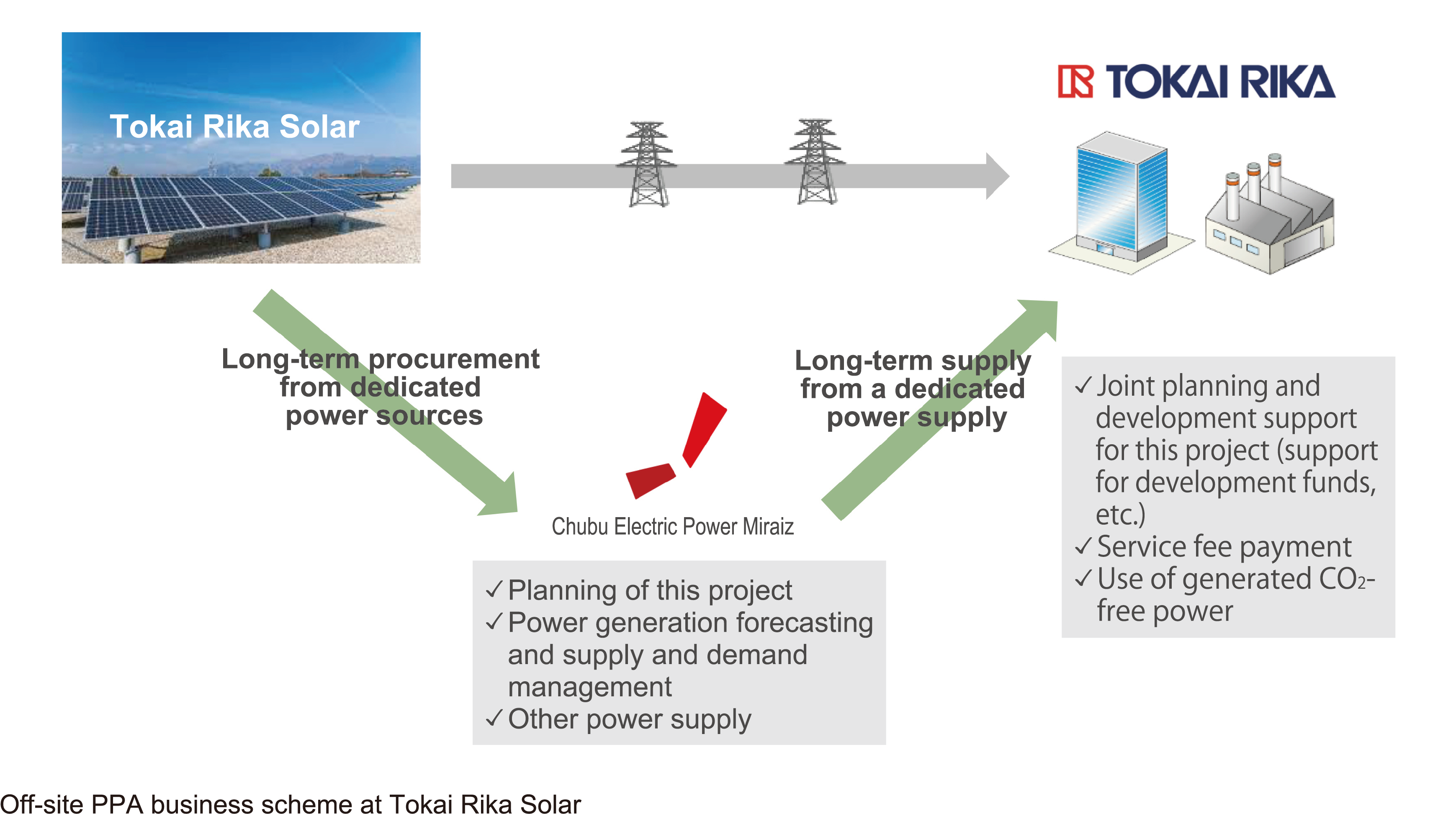

Introduction of renewable energy through the installation of off-site solar power plant

We place importance on the procurement of renewable energy that makes an additional contribution to the realization of a carbon-neutral society, and in addition to installing solar power generation equipment on our premises, we are proceeding to secure off-site renewable energy power sources through off-site PPA. In FY 2022, we will start generating power at our dedicated power plant named ‘‘Tokai Rika Solar’’ in Nagano. Power plants in other regions will sequentially start operating, and we will procure approximately 5,400 MWh of renewable energy annually.

Reduction in Greenhouse Gases

In addition to CO2 emissions from energy use, we are also working to reduce emissions of greenhouse gases*, by using alternatives to reduce consumption and by detoxifying.

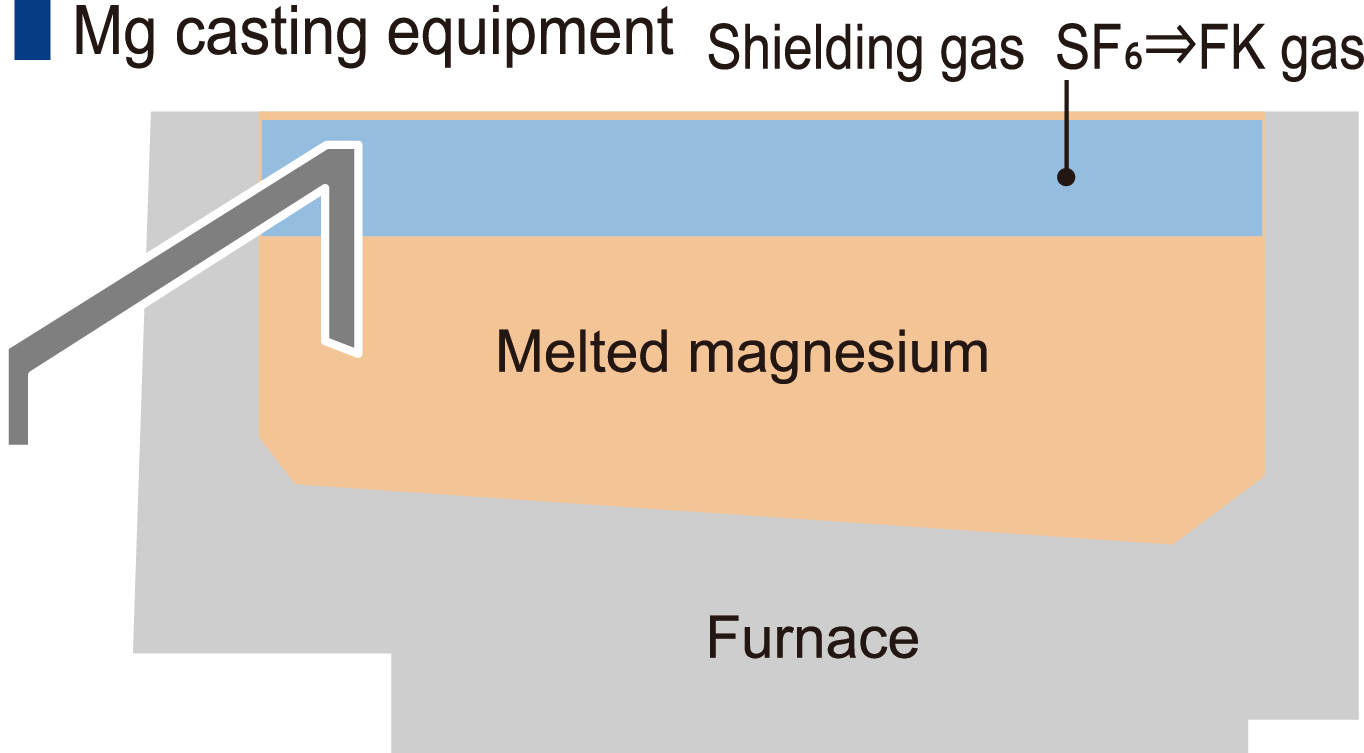

Changeover from shielding gas (SF6) in magnesium casting process

As we are using SF6 for the shielding gas to prevent melted magnesium from burning when exposed to air in the magnesium casting process, we are proceeding with a changeover to an FK (fluorinated ketone) gas with a smaller greenhouse effect. All domestic bases have completed the changeover, and we plan for overseas bases to have completed it in 2030.

*SF6 has high global warming potential, 23,900 times greater than that of CO2, our standard, so it has been specified as one of the targets of emission control.

Reduction of Transportation CO2

We are working to reduce CO2 emissions in the transportation process, such as by improving packing that leads to improved storage efficiency and loading efficiency, and reviewing transportation routes to make them more efficient.

Introduction of hybrid vehicles for distribution trucks

As one of our logistics strategies for realizing CN, we will switch 50% of our logistics trucks to eco-friendly vehicles such as HVs by 2030. In FY 2021, we introduced the first and second HV trucks at our group companies.

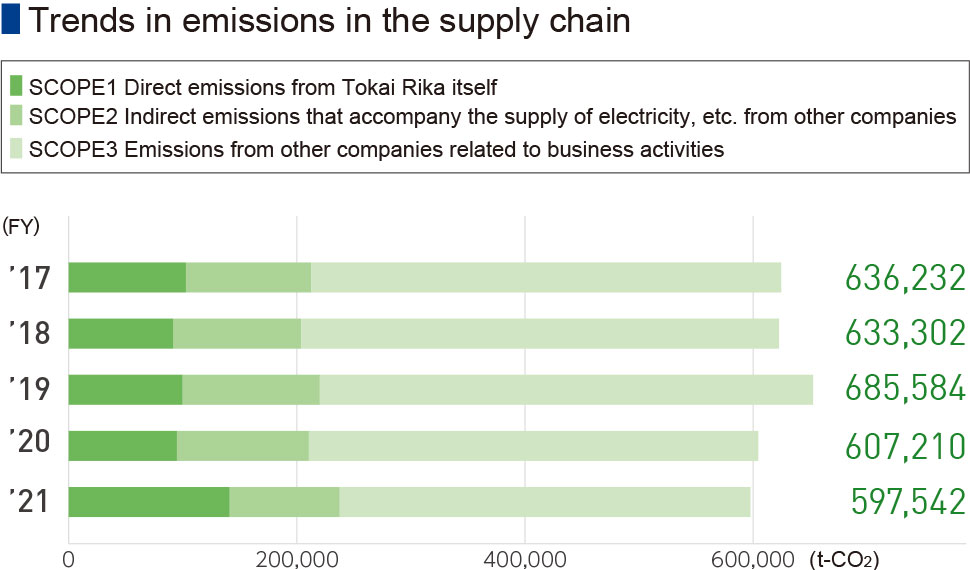

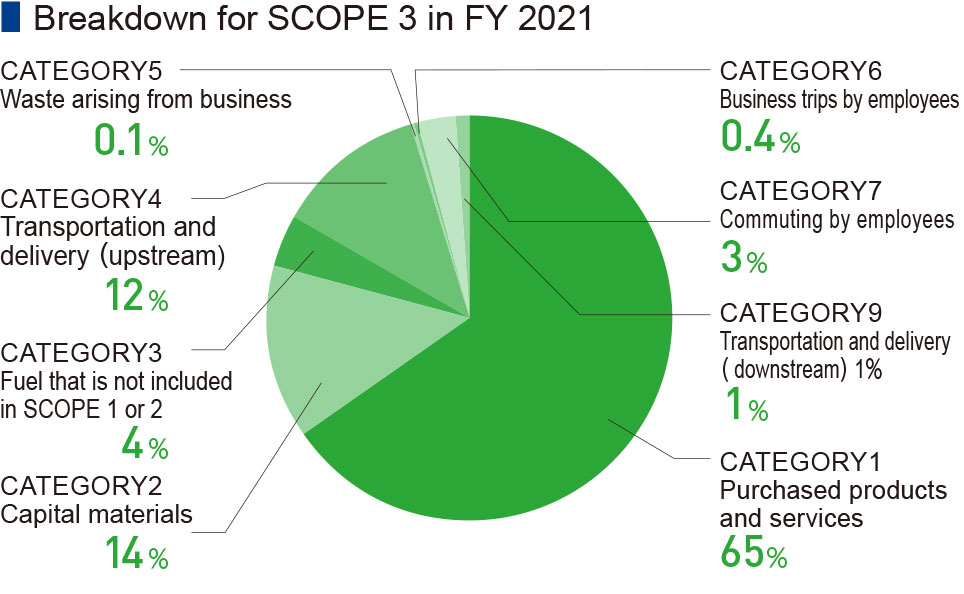

Supply Chain CO2 Emissions

The Tokai Rika Group recognizes that it is necessary to reduce not only CO2 emissions from our own activities, but also throughout the product life cycle in order to curb global warming. Therefore, we monitor CO2 emissions throughout the entire supply chain, including upstream and downstream, and promote reduction activities.